“Generations have been coming in succession, an intact passion for wine-growing with a constant will to respect Mother Nature in its purest form, to let our terroirs express themselves and mature our wines with patience, balance and singularity.”

Our estate

HISTORY

5 generations of passion already

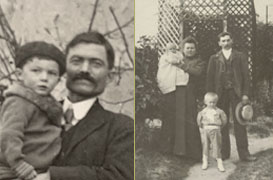

Léonidas Charpentier

1874

It all begins with Léonidas CHARPENTIER, who starts growing wine while working at the farm.

Henri Claisse

1900

Henri CLAISSE, coming from a farm family, will decide in the early 1900’s to start a new activity: wine-growing. His son Marcel CLAISSE will succeed him in the early 1950’s. He will create the Marcel CLAISSE champagne.

Pierre Charpentier

1920

Pierre CHARPENTIER, Léonidas’ son, chooses to become a wine-grower in 1920. He also made red wine to meet the demand… but during the roughest periods, barrels were more expansive than wine itself.

Marcellin Charpentier

1946

3 children were born from the union of Pierre and Marguerite CHARPENTIER, including Marcellin, who succeeded his father 1946 and created his Marcellin CHARPENTIER champagne brand, and in 1954: after marrying Solange, they will 3 children together, including Jacky. 1960: Marcellin dies prematurely. Solange will carry on the work, supported by Jacky and his brother and sister.

Marcel Claisse

1949

Marcel CLAISSE marries Huguette MOUTARDIER, originally from Le Breuil. Together they choose to carry on working in wine-growing as Henri CLAISSE had initiated. From their union Claudine will be born in 1951.

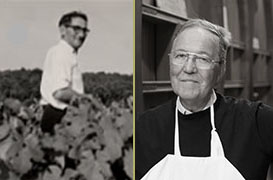

Jacky Charpentier

1969

Jacky CHARPENTIER, who has started working very early on the vineyard, officially becomes a wine-grower.

J. Charpentier

1974

It is only in 1974, when Jacky and Claudine get married, that Marcel CLAISSE and Jacky CHAPRENTIER’s vineyards will gather under the CHARPENTIER champagne banner, the merger is made official with the creation of the J.CHARPENTIER brand. They choose to settle in Villers sous Chatillon a few years later in view to grow the estate. With hard work, precision, patience and passion, the couple has spread the estate, developed the infrastructures and strongly settled the J.CHARPENTIER brand.

Cellar and Traditional Press

1979

Building of a cellar and 4,000 kg traditional press, a true progress

Innovation

1983

a first extension of the cellar is undertaken, then in 1987, a major technological innovation occurs in winery: thermoregulation. Back then, very few wine-growers own this type of equipment.

Jean-Marc et Marie-Pierre Charpentier

1979 & 1988

Claudine and Jacky CHARPENTIER have two children, including Jean-Marc, the eldest born in 1979, and Marie-Pierre the youngest, born in 1988.

Extension

1997

New extension of the cellar and diversification of the vinification methods with 200L barrels and then setting up of several French oak tanks.

Takeover of the vineyard

2003 & 2018

Jean-Marc, who has become an oenologist, will be the first one to come back to the vineyard in 2003 followed by his sister Marie-Pierre in 2018.

VINEYARD

Because we have a strong connection with Mother Nature, we are looking to preserve it, in the purest possible way.

It is a true philosophy that we apply in our daily work through the respect for the land, our terroirs, living things and everything Nature has to offer.

That is why we choose manual work and minimum intervention; ploughing has become part of our daily lives. It is thanks to this approach that we are HVE certified (High Environmental Value)

Enhancing what Nature has to offer

“Preserving our ecosystem through natural means (natural methods to fight grape worms: sexual confusion), sodding on 100% of our parcels to favour rooting of the vine and microbial life, mechanical tillage of the soil (aerating it with ploughing, manual maintenance)”

VINIFICATION

“There is no good wine without good grapes, but there is no good champagne without mastering the art of vinification.

It requires mastery and care, reactivity and patience, balance and singularity.

Our keywords: freshness and body”

It all begins with great quality grapes, pressing within the day to preserve the freshness and the quality. We practice parcel by parcel vinification to find the singular expression of each of our terroirs before we can find the perfect harmony in assembling them. Then we let the wines age to give them time. Disgorging is carried out in our cellars by ourselves, this way we can completely control the quality.

Grape Harvests

The quality and quantity of grapes harvested are the fruit of specific cutting and the rigour of the different operations we carry out. All the grapes are harvested by hand, to make sure that they are intact when they get to the press. We make a first selection during the harvest.

Pressing

Right after harvesting them, the grapes are weighed and join our “qualitatif Champagne” certified pressing centre. They are pressed in one of our 2 Champenois presses (4,000 kg or 8,000 kg). We practice pressing by parcel, by cru and by variety. We extract the juice very gently and following a specific division in order to get the purest, best juice. All of our grapes are pressed on the very day of their harvest to preserve the freshness of the aromas.

Maturation and vinification

The wines are matured in stainless-steel vats, in barrels or in oak tanks. Each parcel is vinified autonomously. This vinification allows us to highlight the typicity of each terroir. After several months of maturation, characters assert themselves, each terroir is associated to its variety and to its harvest year and will have its own identity.

Blending

Then comes the blending stage where we taste, appreciate, discover and describe each clear wine one by one…which is a little over 70 samples. Clear wines intensify the typicity of the aromas. Like artisans, during blending, we “create” tomorrow’s wines, still constantly looking for freshness and body, which are the characteristics of our house.<br /> These tastings are carried out by members of the CHARPENTIER family, under the influence of Jean-Marc, oenologist, and son of the house.

Bottling and ageing

Once the blends are determined, we bottle the wine; which is called “drawing”. Each bottle is placed laying down in the cellar for a maturing period during which the second alcoholic fermentation will take place. We have chosen to mature our wines longer, for blossoming, opening the aromas and highlighting the complexity of each cuvée takes time. Patience is required.

Remuage, disgorging and packaging

Two to ten years have passed, each bottle is then moved, partly manually on the racks, and another part automatically on gyropalettes and then disgorged and dosed out. We practice moderate dosage to allow for the aromas’ natural expression. Finally, we always use corks to seal our bottles. The bottles will spend a few more months resting before they are sent away.